Related Products

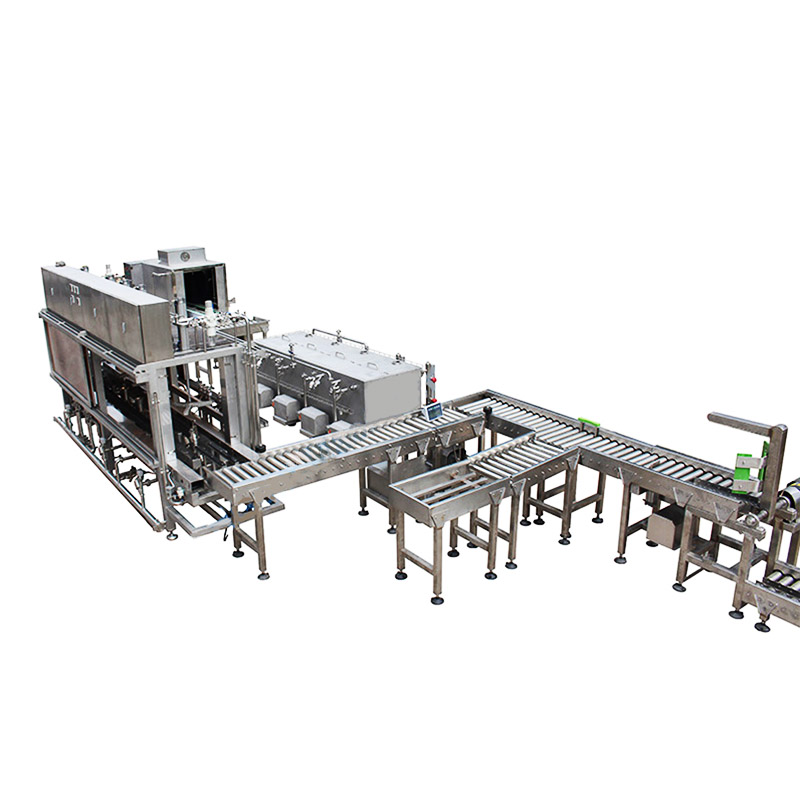

| Place of Origin: | Shandong, China |

|---|---|

| Material: | AISI 304 Food Grade stainless steel |

| Model: | TRCFA6-33S |

| Payment Terms: | T/T, L/C |

| Delivery time: | 25-30 working days |

| Supply Ability: | 30000 Pieces per Year |

Copyright © 2025 Yantai Trano Co.,Ltd. | All Rights Reserved