BETTER TOUCH BETTER BUSINESS

Contact Sales at TRANO.

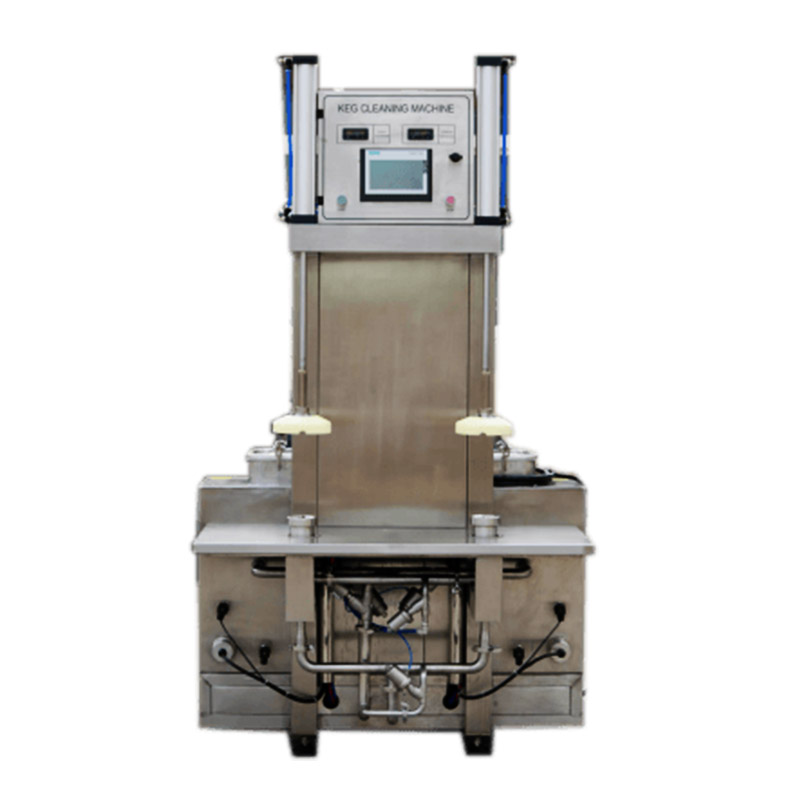

| TRCA2-22E-T-H-1 | Beer Keg Two Heads Washer | |||||||||

| Matching Parameter | Two pumps、two tanks without insulating layer is default choice | ||||||||

| Tank Parameter | Two tanks,single tank 100L without insulating layer, one is caustic tank,the other one is hot water tank. | |||||||||

| Heater Way | Electrical heater in caustic tank and hot water tank | The table can rise or not | No | |||||||

| Tank Insulating Layer | No | Add insulating layer | ||||||||

| Spear Type | S/D/A/G type (Choose one of them) | Wheels or feet | Feet | |||||||

| Power | 380V 3phase 50Hz 14KW | According To Customers Power Standard | ||||||||

| Size(L*W*H) | 1.25*1.58*2.03M package: 1.40*1.70*2.25M | Package | Composite Borad Box | |||||||

| Equipment explaination | 1、It is use the Siemens PLC200 controller and Schneider ,Taiwan AirTAC solenoid valve,pump is Chinese Yuehua. 2、The cleaning process adds unique hot caustic washing and steam sterilization function . 3、The whole machine use the stainless steel AISI304. Pipeline welding uses German automatic pipe welding equipment, one-time welding double-sided forming. Washing working procedure: Pressing → air blowing/drain off → city water washing → air blowing/drain off → hot caustic washing → air blowing/to caustic box → rinse water washing→ air blowing/drain off → hot water 1 washing → air blowing/drain off → hot water 2 washing → air blowing/ drain off → steam sterilized(drain off) → steam keep pressure sterilized → CO2 blowing/drain off →CO2 pressure filling | |||||||||

WASHING WORKING PROCESS

Impact-air blowing/drain off-water washing-air blowing/adrain off - hot caustic washing spear- hot caustic washing-air blowing to caustic tank-hot water washing spear-hot water washing- airblowing /drain off-acid washing spear-acid washing-air blowing to acid tank- hot water washing spear- hotwater washing-airblowing/drain off-steam sterilized-steam retaining-CO2 blowing/drain off-pure water (To make the keg cool)-CO2 blowing/to hot water tank-CO2 pressure preparing -cylinder return.

Copyright © 2025 Yantai Trano Co.,Ltd. | All Rights Reserved